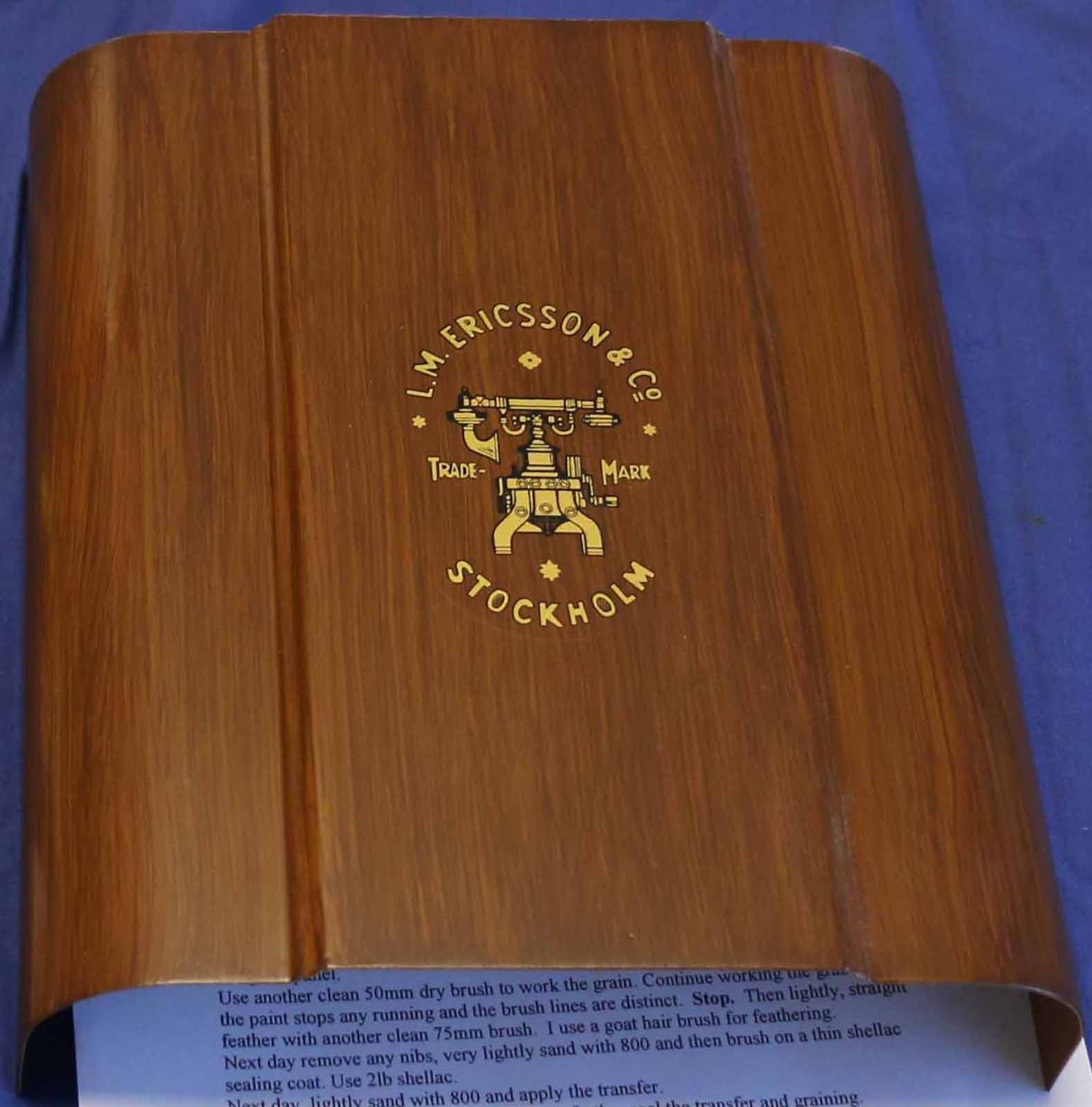

Walnut Wood Graining

For Ericsson Battery Covers and Rolled Fronts

By John Newgrain

Base Coat

Strip the old finish, sand, fill, clean, etc and dry the metal panel. Using a spray can, apply automotive acrylic primer/surface, sand with 400 paper to achieve a flat, smooth surface for an Al finish.

Paint the front with Wattyl low sheen acrylic colour “Rich chocolate ,” code 24A-1A”. Paint the back with the chocolate base, or satin black which is sometimes used.

The paint can be applied with a quality fine haired brush or spraying. After allowing a day to dry, sand very lightly with 600 wet and dry paper.

To spray, thin the base brown coat by approx 20% or to a “thin cream” to spray @ 50psi. Remember, too thin and it will run. Spray a few thin mist coats to achieve the desired finish. Lightly sand off any nibs with 600 paper and 3M Superfine flexible sanding pads, or Norton Soft touch sanding sponge etc Let it dry for 24hrs.

Hint: A strong magnet with the pole faces covered with plastic tape to prevent scratching, is a way of holding the work.

Graining

Using a 25mm paint brush, rough brush in the direction of the grain, a grainy coat of the mixture of (acrylic mission brown with 2% black added), JOSONJA’S GEL RETARDER and water. Approx. 60%paint, 20% “Retarder” and 20% water, well mixed. That is, 3 small tea spoons of paint, 1 spoon of water, 1 spoon of Gel retarder.

I usually dip a 25mm brush into the “paint mixture”, remove excess by dabbing it onto a sheet of news paper and then quickly apply the brush to the work. Run a full length thin to medium coat that just covers the base coat and then re run over it to create the grain. Put a bit of a wave on the front of the panel. Work quickly from one edge to cover the complete panel.

Use another clean 50mm dry brush to work the grain. Continue working the grain until the paint stops any running and the brush lines are distinct. Stop. Then lightly, straight feather with another clean 75mm brush. I use a goat hair brush for feathering.

Next day remove any nibs, very lightly sand with 800 and then brush on a thin shellac sealing coat. Use 21b shellac.

Next day, lightly sand with 800 and apply the transfer.

Next day, a single brush coat of shellac to further seal the transfer and graining.

Finishing

The next day a very light 800 sand and spray with estapol satin. Usually 1 coat is sufficient. Of course you could omit using the estapol satin and totally finish the panel by French polishing it.

This article first appeared in Adelaide Central Volume 2.6 - July-August 2016